Product Introduction

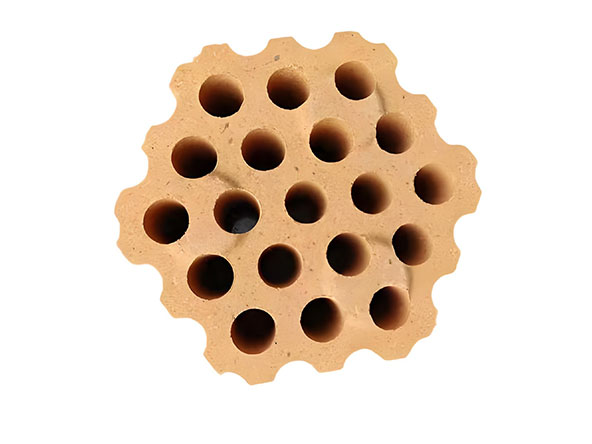

Checker bricks are a type of refractory bricks used in hot blast stove. They are mainly used in the middle and upper part of the checker chamber of the hot blast furnace to store heat. They play an extremely important role in heating cold air into hot air.

Product Advantage

- Large heat storage area, smooth ventilation,

- small resistance, strong heat exchange capacity,

- good volume stability, excellent high temperature load creep performance,

- high density and low porosity.

Application Field

Checker bricks are mainly used as heat storage bodies in hot blast furnaces. When the hot air temperature is lower than 900°C, fireclay checker bricks are generally used. When the air temperature is 900°C, high alumina bricks, mullite bricks, sillimanite bricks and silica bricks are used.

Product Data

| Items | Low creep fireclay checker brick | Low creep high alumina checker brick |

| Al2O3 % ≧ | 48 | 65 |

| Fe2O3 % < | 2.0 | 1.8 |

| Bulk density g/cm3 | 2.2 | 2.6 |

| Cold crushing strength Mpa | 50 | 60 |

| Refractoriness ℃ | 1730 | 1790 |

| Creep rate % | 0.2Mpa*1280℃*25h-0.45 | 0.2Mpa*1450℃*50h0.8 |

Related Products:

1. Traditional 7-hole checker brick: the hole diameter is 43mm, and the heat storage area is 38.1m2/m3;

2. 7-hole checker brick: the hole diameter is 30mm, and the heat storage area is 47.08m2/m3;

3. 19-hole checker brick: the hole diameter is 30mm, and the heat storage area is 48.6m2/m3;

4. 31-hole checker brick: the hole diameter is 25mm, and the heat storage area is 58.1m2/m3;

5. 37-hole checker brick: the hole diameter is 20mm, and the heat storage area is 68.7m2/m3.