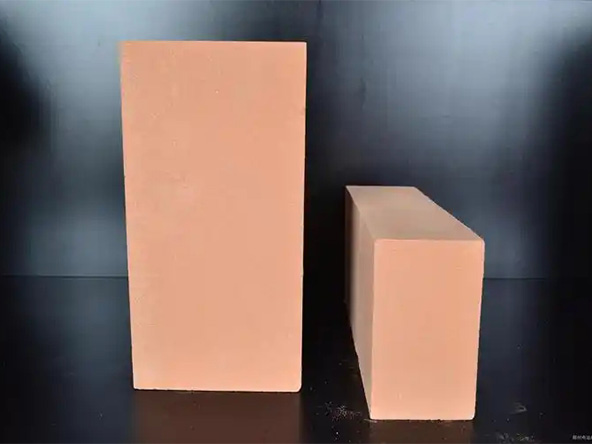

Product Introduction

Fireclay insulation bricks are lightweight refractory products containing 30% to 46% Al2O3. They are made of clay clinker or lightweight clinker and plastic clay as the main raw materials and are produced by sintering. The ingredients are mixed with water to form a mud material, which is extruded and dried before being sintered in an oxidizing atmosphere at 1000-1250℃.

Product Advantage

Fireclay insulation bricks can effectively reduce the weight of the furnace lining, have a light volume density, and play a role in heat preservation and energy saving.

Product Data

| Items | NG-1.0 | NG-0.8 |

| Al2O3 % ≥ | 42 | 42 |

| Fe2O3 % ≦ | 2 | 2 |

| Reheat linear change ℃ | 1350 | 1250 |

| Bulk denstiy g/cm3 | 1.0 | 0.8 |

| Cold crushing strength Mpa ≧ | 3 | 2.5 |

| Thermal conductivity w/(m.K)≤ | 0.5 | 0.35 |

Application Field

Fireclay insulation bricks are mainly used in thermal insulation layers that are not in contact with molten materials and have no corrosive gas effects. The commonly used lightweight clay bricks have a volume density of between 0.7-1.2g/cm3.