Product Introduction

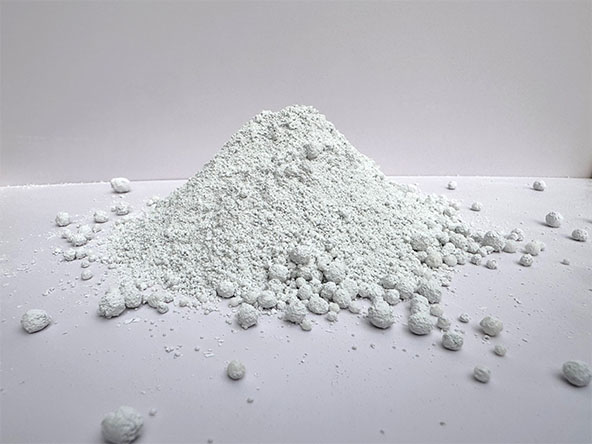

Lightweight insulation castable is made of lightweight aggregate and powder, binder and admixture. The true porosity of lightweight castable is above 45%. The main components are lightweight aggregate, and it is made of high-quality raw materials such as hollow alumina balls, floating beads, ceramsite, micropowder, binder, admixture, etc.

Product Advantage

Low density

It has low density, low thermal conductivity, good thermal insulation performance, good overall air tightness after masonry, and can repair various parts and shapes.

Thermal insulation

Lightweight castable is easy to construct and is used as the thermal insulation layer of the lining of industrial kilns. It plays a role of thermal insulation at a temperature of 600℃-1400℃. While the furnace wall and the furnace roof are insulated, the light density reduces the weight of the lining and saves energy.

Easy to construct

Lightweight castable is easy to construct and is used as the thermal insulation layer of the lining of industrial kilns.

Product Data

| Items \Brand | QJ-1400 | QJ-1300 | QJ-1200 | QJ-1000 | QJ-800 | |

| Service temperature ℃ | 1400 | 1300 | 1200 | 1000 | 800 | |

| Bulk density g/cm3 | 1.5 | 1.2 | 1.0 | 0.8 | 0.5 | |

| Cold crushing strength MPa | 110℃ dried | >5 | >4 | >3.5 | >2.5 | >0.3 |

| Service temperature | 7 | 6 | 4.5 | 4 | 0.5 | |

| Permanent linear change 3hr ≤2% ℃ | 1400 | 1300 | 1200 | 1000 | 800 | |

| Thermal conductivity(350±10℃)W/m.k | 0.5 | 0.4 | 0.3 | 0.22 | 0.18 | |

Application Field

Lightweight castables are used in the electric power, chemical and metallurgical industries, which can save 20% of energy. If the lightweight thermal insulation castable has a high wear resistance coefficient, it can be used for thermal insulation layer, and can also be directly used as a refractory high-temperature lining working layer.