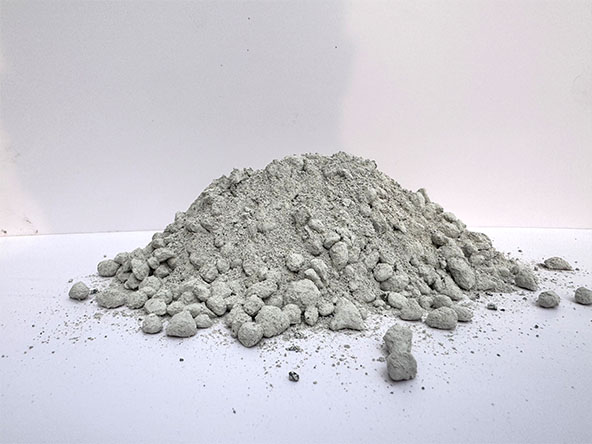

Product Introduction

Non-stick alumina castable is made by adding ultra-fine powder technology to the castable to reduce the porosity and pore diameter of the castable, so that the porosity of the non-stick aluminum castable is reduced to less than 10%, preventing the adhesion and penetration of aluminum liquid. When used in aluminum melting furnaces, it does not stick to aluminum liquid, does not hang slag, and does not produce aluminum ash. It not only reduces the reaction between aluminum liquid and non-stick aluminum castable, but also improves the quality of aluminum alloy.

Product Advantage

- Non-stick alumina castable also has high density, high strength and stable thermal shock resistance.

- By adding an appropriate amount of non-stick aluminum powder in the process greatly reduces the wettability of aluminum and alloys and slag to the lining

- Improves the corrosion resistance of the castable to aluminum liquid containing chemical components such as salt and solvent, that is, it prevents aluminum and alloys and slag from penetrating into the castable, and also extends the life of the furnace lining.

Product Data

| Items\Brand | GMJ-A | GMJ-AP | GMJ-GP | |

| Al2O3% ≥ | 65 | 70 | 75 | |

| Bulk density g/cm3 ≥ | 2.4 | 2.65 | 2.75 | |

| Cold crushing strength Mpa≥ | 110℃×24h | 40 | 45 | 45 |

| 1300℃×16h | 45 | 50 | 55 | |

| Modulus of rupture Mpa≥ | 110℃×24h | 12 | 15 | 15 |

| 1300℃×16h | 14 | 18 | 18 | |

| Reheat linear change 1300℃×3h % | ±0.1 | ±0.1 | ±0.1 | |

| Application | Furnace door, furnace door frame, slag slope, feeding port | |||

| Material characteristics | High strength, high wear resistance, impact resistance, and spalling resistance | |||

Application Field

Non-stick alumina castable is applied for aluminum melting furnaces, rever-beratory furnaces, double stone furnaces, aluminum water bags and other furnaces, and is widely used in the aluminum smelting industry.